Intelligent high-definition three-dimensional borehole imaging system,borehole imaging system

Abstract

The intelligent high-definition 3D borehole imaging system uses a new type of probe with an open lens, combined light source, and manual or automatic electric control lifting device. It can accurately identify lithology, investigate geological structures, determine soft mud interlayers, detect faults, cracks and broken zones, monitor groundwater migration, etc. In the field of engineering construction, it can also be used for the detection of reinforced concrete, the evaluation of concrete engineering effects, auxiliary geotechnical engineering testing, the monitoring and prediction of geological disasters, the guidance of underground instrument installation, the detection and inspection of underground pipelines, and the preliminary exploration of tunnel excavation.

Working principle

Under the illumination of visible light source, the camera of the well imaging instrument (downhole television) takes pictures of the inner wall of the casing and the wellbore, and the electronic circuit of the well imaging instrument (downhole television) amplifies the image signal to generate a frequency pulse signal, and transmits the pulse signal to the ground receiver through a single-core cable or a multi-core cable for amplification and decoding, thereby generating the same image as the downhole camera.

Applications

● Check the quality of concrete pouring and the effect of grouting treatment

● Monitoring and detection of geological disasters

● Guide the installation of underground instruments and equipment

● Inspection and detection of underground pipeline and advance detection of tunnel excavation

● Divide lithology, find out geological structure and determine weak argillaceous interlayer

● Detection of faults, fissures and fracture zones

● Observe groundwater activity and assist in Geomechanical test

● Coal well, oil well detection, etc

Features

● 360° Panoramic Imaging

Using 360 ° Panoramic HD ultra low light camera, the front end of the probe adopts an open toughened glass hemispherical cover, which can take a 360 degree omni-directional camera of the drilling wall.

● Ultra HD + true color

Standard 5 megapixel high-definition lens, digital image color realistic, 1:1 imaging, picture amplification without Mosaic, crack resolution up to 0.01mm.

● Stitching pictures+ video Combination

By using efficient intelligent image unfolding algorithm, when the probe is pulled up and down, it can seamlessly and quickly make a mosaic and video recording, and save and play back the whole cylindrical unfolding drawing of the wellbore and the downhole forward-looking video in real time.

● Auto Detection

Using stepper motor to lift and lower the probe at a constant speed can avoid the problems of image jitter and depth error caused by manual cable lowering.

● 3D high-definition Sensor

Built in high-precision electronic compass, three-axis sensor, accuracy of up to ±0.1°。 It can measure all kinds of vertical holes, inclined holes and horizontal holes.

● Software

The electronic core library of hole wall high-definition image data replaces the physical core to solve the problems of core sampling, transportation, storage and management.

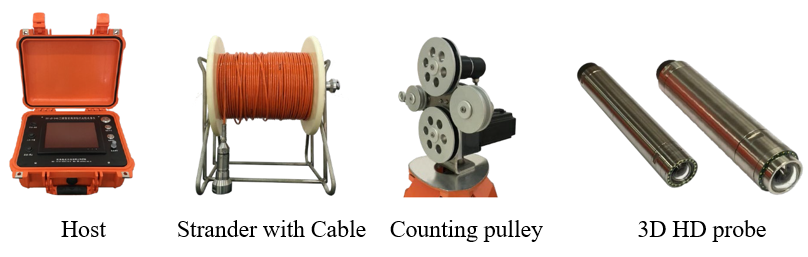

Configuration

Specifications

Imaner | Multi-media processing industrial control machine |

Operation | Touch screen + button |

Display | 8.4-inch TFT LCD |

Storage | 128G high speed solid state hard disk |

Collecting speed | Up to 60 frames per second |

Output picture | >2048*2048pix |

Collecting mode | Real-time image mosaicking, real-time video recording, real-time image mosaicking and video recording |

Host size | 350*300*150mm |

Host weight | 3.5KG |

The lens type | 3600 Panoramic lens |

Open Camera | The probe camera use hemispherical explosion-proof glasscover, with no shielding in front, and easy to disassemble andreplace |

Probe resolution | 2-10 megapixels |

Probe diameter | Ф50mm,Ф63mm(others on request) |

Probe lifting mode | Uniform electric lifting |

Probe lifting speed | 0.5~3.0m/min |

Length of the cable | 100~1500m(customizable) |

Counting accuracy | 0.lmm |

Open light source | Open waterproof LED ring light source design, no deadAngle, no gouge, better imaging effect in the hole |

3D sensor | 3d attitude sensor is adopted to indicate the attitude of theprobe in the well in real time, supporting the detection ofvertical hole, horizontal hole and inclined hole |

Cable | Customized cable,100m cable weight <2kg, tensile resistancemore than 200kg |

Sensor accuracy | Crevice accuracy:0.lmm, azimuth accuracy:0.1° |

Battery life | 8 Hours |